The main bearing of the CT machine is applied at the connection between the fixed CT frame and the rotating scanning part, and is a key component of the rotating scanning part of the CT machine. It is used to transmit and withstand axial loads, radial loads, and overturning moments generated by X-ray tubes, collimators, detectors, sliding rings, and other devices. It must meet the requirements of high speed, low noise, high accuracy, low vibration, and long service life of the CT machine.

The company has been committed to the research and development and manufacturing of high speed and low noise medical CT machine bearings and industrial CT machine bearings. It has established a dedicated CT machine bearing production line, advanced production equipment and testing instruments, and has developed more than 20 models of CT machine spindle bearings, which have been mass-produced and meet the technical indicators of imported new bearings.

Main product structure: Four point contact ball disc bearings, double row angular contact ball bearings, thin-walled paired angular contact ball bearings, steel wire raceway bearings, etc. The outer dimensions range from inner diameter 680mm to outer diameter 1440mm, and the rotational accuracy of the bearings does not exceed 0.05mm. The working speed is within the range of 60-150r/min, and the vibration noise value does not exceed 65dB, meeting the technical indicators of imported bearings from abroad. It has successfully replaced well-known brands such as Kaydon, Franke, Rothe Erde, etc.

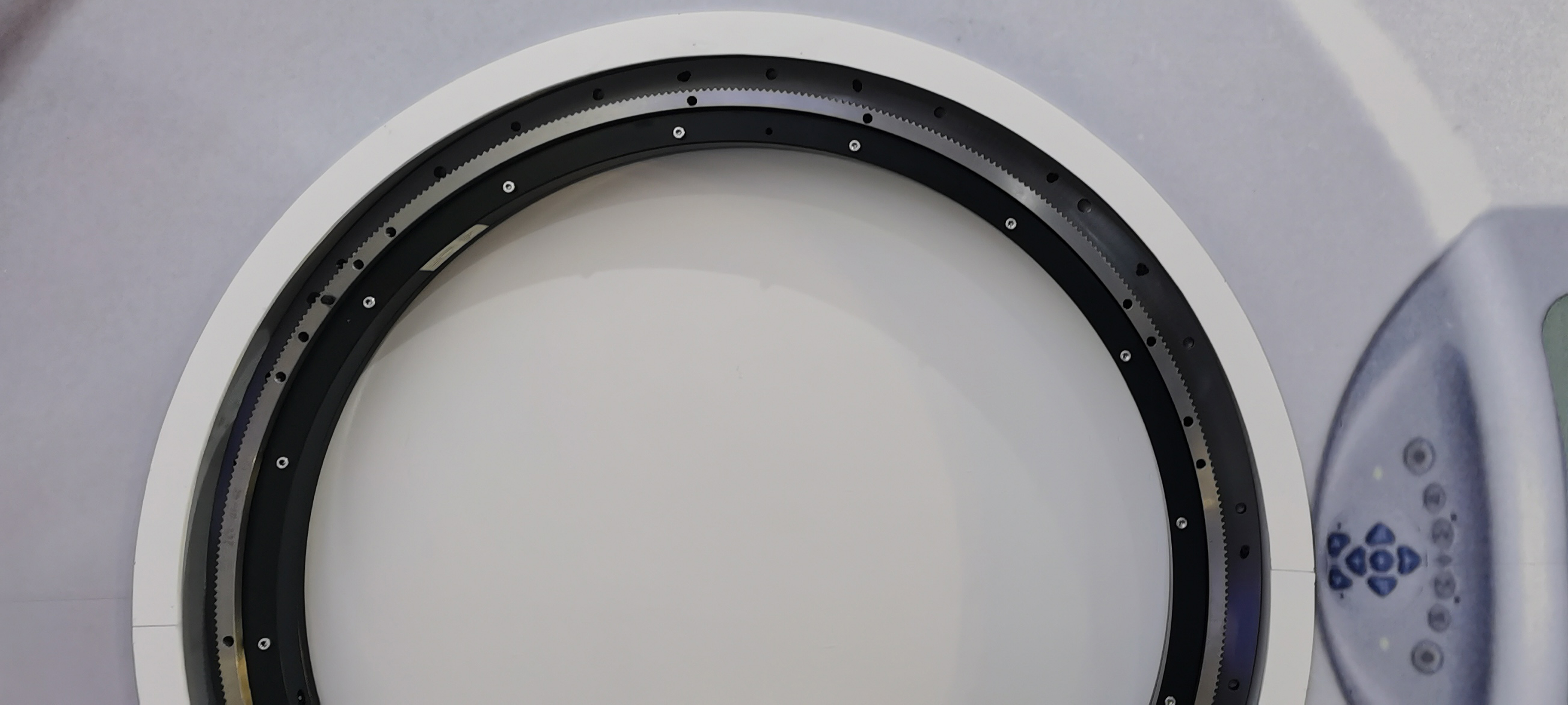

Thin walled paired angular contact ball bearings

External dimensions:

φ 889 x φ 959.8 × 50.8mm

Bearing speed: 80-120r/min

Rotation accuracy: P5 level

Noise: less than 64dB

No load starting friction torque: 40N M

2024-03-11