High temperature bearings

Reduce maintenance. Run longer. Run cleaner.

Bearings operating in high temperature applications can be unreliable due to premature failure. The result is high costs and time wasted on frequent bearing replacements.

We offer solution with an assortment of bearings designed to reduce maintenance, run longer and cleaner in high temperature applications.

High temperature bearings run trouble free

High temperature bearings incorporate a graphite-based lubrication that continuously lubricate the bearing, eliminating the use of grease and oil. Ideal for applications in

industries such as metals and food & beverage, these bearings are designed for trouble-free operation at temperatures up to 350 °C (660 °F).

We provide:

• Reduced total operating cost through increased bearing service life

• Relubrication-free operation

• Reduced machine complexity

• Reduced environmental impact

• Excellent performance in hot conditions, dry environments and applications with low rotational speeds

Common issues in high temperature applications

Bearings operating in high temperature applications may be impacted by a number of factors that can reduce bearing service life. Common issues include:

Inadequate lubrication

At high temperatures, lubricating grease or oil becomes very thin. Oil that is too thin, in combination with low rotational speeds, results in metal-to-metal contact in the bearing. This will cause wear, leading to noise and excessive play!

Short grease life

Grease ages rapidly at high temperatures, resulting in the need for very frequent relubrication. This is time consuming and costly and is a task that can be forgotten or even neglected. Frequent relubrication also

creates the potential to over-fill the bearing, increasing the risk of excess grease contaminating the process and possibly catching fire.

Additionally, old grease left in the bearings can carbonize at high temperatures and block the bearings.

Loss of internal bearing clearance When temperatures rise above the bearing stabilization temperature, thermal expansion and material structural changes will occur in the bearing. This can lead to an uncontrolled loss of internal radial clearance, and ultimately seized bearings.

MONTON high temperature bearings are designed for challenging operating conditions, with

variants capable of performing at temperatures as high as 350 °C (660 °F).

These bearings incorporate graphite-based lubrication which can lubricate at high temperatures and low speeds, eliminating the risk of metal-to-metal contact. Unlike grease and oil, graphite does not age and will

not lose its lubricating properties at temperatures up to 350 °C (660 °F). This eliminates

the need to relubricate high temperature bearings. Additionally, these bearings are designed with a special radial clearance specified to maintain the required radial clearance at high operating temperatures.

This avoids bearing seizure and enables a long service life.

Advantage:

optimum performance, efficiency and savings

MONTON high temperature bearings are designed to deliver increased reliability, reduced complexity, and decreased environmental impact. Because high temperature bearings correspond to the ISO boundary dimensions for standard bearings, production efficiencies and cost savings can be realized with a

simple change to high temperature bearings.

Customer benefits

Increased reliability, reduced maintenance

By eliminating temperature related bearing failures, high temperature bearings improve machine uptime, output and overall reliability.

The solution also eliminates the need to frequently relubricate bearings operating at high temperatures. This provides greater peace of mind, while enhancing operational efficiencies and cost savings.

Reduced complexity

Because high temperature bearings are designed for relubrication-free operation at temperatures up to 350 °C (660 °F), manual and automatic lubrication systems are

eliminated along with their related costs and issues. Complex cooling systems used to reduce bearing operating temperatures may also be unnecessary.

Reduced environmental impact

Global factors

These products are designed to reduce environmental impact and contribute to sustainability efforts.

Workplace and process safety

With grease removed from the process environment, relubrication procedures in potentially dangerous areas of the operation can be avoided. Slippery surfaces from

grease leakage and the risk of excess grease catching fire are eliminated. High temperature bearings also contribute to food safety, because there is no risk of process lines and products being contaminated by grease.

Industries performance

High temperature bearings provide solutions that are proven in a number of different applications across a variety of industries. Even if the design and purpose of the bearing applications differ greatly, they all share

common operating conditions that are ideal for graphite lubrication.

Examples of successful installations :

Cooling bed for steel plates

In hot rolling mills, extremely large cooling beds accumulate and allow steel plates to cool. They use thousands of bearings, operating in intense heat standing still or rotating very slowly. A customer operating this application was using grease lubricated deep groove ball bearings with C4 radial clearance.

Customer issues

The large number of bearings required large amounts of grease, making relubrication costly, difficult and time consuming. Rollers that would not rotate due to seized bearings created scratches on the steel

plates. Replacing failed bearings was causing costly downtime.

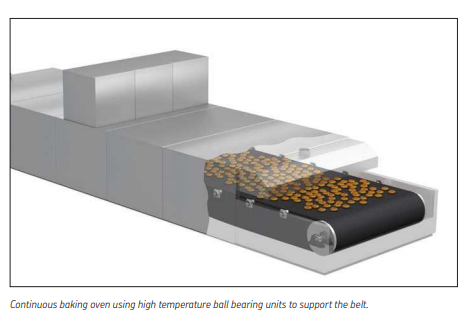

Continuous baking ovens

Continuous baking ovens are used by largevolume industrial bakeries. Requirements for throughput and reliability are very high.

Bearings rotate slowly and are exposed to high temperatures. A customer was using grease-lubricated ball bearing units in a continuous baking oven.

Customer issues

High operating temperatures caused inadequate lubrication, increased wear in the bearings, poor reliability, unplanned stops and ultimately failure. Frequent relubrication using expensive high temperature grease required costly maintenance, while used grease ejected from the bearings created a risk of food contamination and worker safety issues.

Wafer baking ovens

Producers of confectionary products use fully automated wafer baking ovens for highvolume production. A food and beverage manufacturer running this process was using deep groove ball bearings lubricated

with high temperature grease.

Customer issues

Bearing relubrication was needed every 16 weeks, requiring costly planned maintenance. Grease leakage impacted food safety. Output was limited by the oven temperature restrictions of grease-lubricated bearings.

Paint lines

Paint lines are conveyor systems that transport parts as they are painted and dried. For one customer, the bearing operating temperature in the drying section was up to 200 °C (390 °F). Deep groove ball

bearings lubricated with high temperature grease needed frequent relubrication.

Customer issues

Painted car chassis frequently needed to be reworked due to paint damage caused by lubricant leakage from the bearings. Grease could stain the drying paint, an issue made worse when water-based paints were used.

The high temperature greases used were not PWIS-free (Paint-Wetting Impairment Substances). Damage to the paint on chassis parts caused production stops.

Assortment

We offers a wide assortment of high temperature bearings and units according to ISO standards and also an assortment of customized high temperature bearings.

Selection of an appropriate high temperature bearing is based on the bearing type and the operating conditions (primarily the temperature and speed) of the machinery.

The basic assortment of high temperature bearings and bearing units corresponding to ISO standards includes:

• Deep groove ball bearings

• Insert bearings

• Ball bearing units

The assortment includes variants that contain food-grade solid lubricants registered by NSF as category H1 (lubricant acceptable with incidental food contact for use in and around food processing areas).

In paint line applications, it is critical that the paint quality of the end product is not impaired by contamination. To address this need for high temperature paint lines, we offers a high temperature bearing variant VA292 that has the same bearing characteristics as version VA228

but, in addition, comply with common PWIS standards (Paint Wetting Impairment Substance).

Customized high temperature bearings

In addition to high temperature bearings corresponding to ISO standards, we offers an assortment of customized high temperature bearings.

These bearings are customized for use in equipment such as automatic wafer baking ovens in the food and beverage industry, in industrial furnaces and in chains like customized cam rollers. For additional information, contact with us.

Deep groove ball bearings for high temperature applications

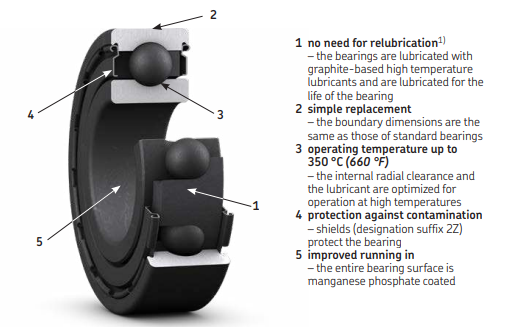

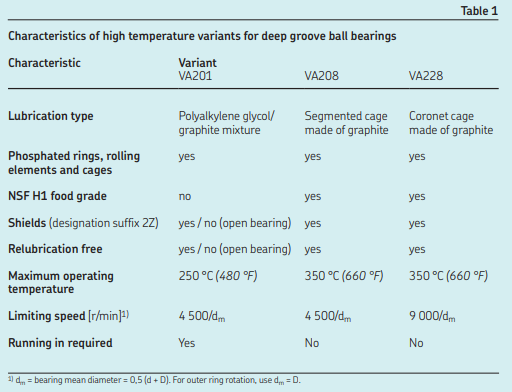

The range of deep groove ball bearings for high temperature applications provides solutions for various combinations of operating temperature and speed. All variants are lubricated for the life of the bearing, except for open VA201 bearings (that is, without integral shields) which require relubrication.

VA228 – SKF highest performance at temperatures up to 350 °C (660 °F) VA228 is an excellent choice for machinery operating with low speeds or oscillating movements in combination with very high operating temperatures. This bearing offers outstanding performance at temperatures up to 350 °C (660 °F) through the combination of the solid graphite cage, an adjusted high temperature bearing radial internal

clearance and integral shields.

VA208 – Improved performance at temperatures up to 350 °C (660 °F) The VA208 bearing is lubricated by a segmented graphite cage. The large amount of lubricating graphite gives a long service life at temperatures up to 350 °C (660 °F).

VA201 – Basic performance at temperatures up to 250 °C (480 °F)

The VA201 bearing is lubricated with a polyalkylene glycol/graphite mixture suitable for temperatures up to 250 °C (480 °F). Version VA201 is an open bearing (without shields) while the 2Z/VA201 has an integral shield on both sides. Both versions are supplied pre-filled with lubricant. VA201 can be re-lubricated whilst-2Z/ VA201 is lubricated for the life of the bearing. Depending on the speed and operating temperature, a special running-in procedure might be required .

Features and benefits of high temperature deep groove ball bearings

For more inforamtion, welcome contact with us.